Documentation >

MAC-PAC Reference Library >

Distribution >

Order Processing >

Key Concepts and Procedures >

Relief Codes and Balance Types >

Tracking Inventory

Tracking Inventory

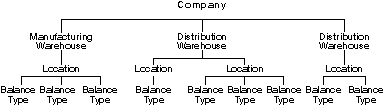

Inventory levels are tracked at various levels throughout MAC-PAC. Each stockkeeping unit in the system is assigned to a particular physical location within a particular warehouse. These physical locations are called stockkeeping locations. Inventory status inquiries and reports then allow you to see how many items are at each stockkeeping location across the system.

In addition to specifying where an item is located, you also specify how it should be used. Balance types are used for this purpose. At a given location, different boxes of the same item might be stored in different balance types, depending on their purpose. For example, one box could be intended for sale to customers, a second could be intended for use on the shop floor, and a third could be waiting for quality inspection. Separate balance types can be defined to describe each of these situations.

Stock status information identifies the balance type as well as the physical location for each item. Inventory can be moved between companies, warehouses, stock locations, and balance types using the stock transfer transaction. The figure below illustrates these relationships.

Structure for Tracking Inventory

You can also track inventory by lot. Lot control is a way of indicating items that were made or received in the same batch or that share the same characteristics. However, they are not related to particular physical locations. Items from the same lot can be stored in different balance types at different stockkeeping locations. The Lot History Report allows you to see every location where a lot is stored. Note that inventory cannot be moved from one lot to another.